top of page

Steelmaking Defects

Slivers/laminations

Slivers are can either be "open" or "closed" (laminated or delaminated). They can appear randomly or continuously throughout a coil. Slivers are caused by non-metallic debris - frequently mold powder - being pressed into the surface during casting. Rolling at the hot strip mill causes the elongated, chevron shape.

Seams

A continuous casting defect, usually down the center of the coil.

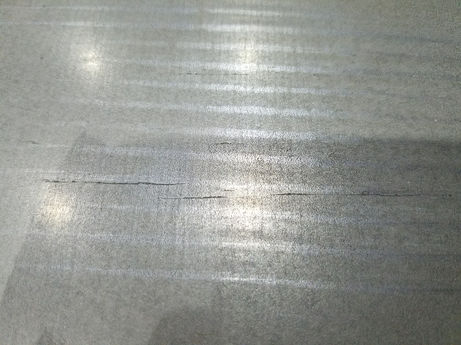

Caster Folds / Longitudinal Cracks

A thin, jagged crack parallel to the rolling direction. Caster folds are usually created by uneven cooling during casting.

bottom of page